More power in less space

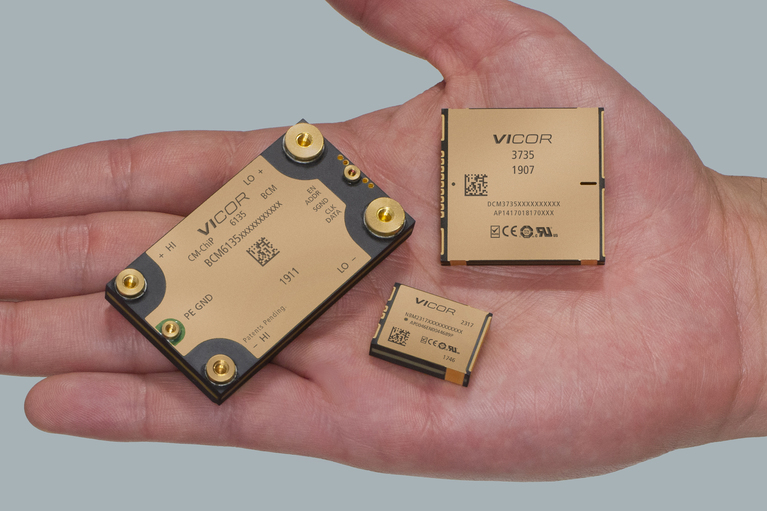

One of the central challenges facing the automotive industry is the need for more power in less space. EVs employ over 50kW of electrical power, compared to less than 3kW in an ICE vehicle. The nearly 20x increase in power requires compact power solutions to free up space and weight. Reducing the size and weight of the power delivery network are essential factors. For example, 2.5kW of power from the Vicor BCM6135 can be held in the palm of your hand and weighs only 65 grams.

The modular approach to power

High performance power modules

Using miniaturized power modules with up to 5x the density, the modular approach uses less real estate, leaving more room for functionality. High efficiency modules require much simpler thermal management and allow for flexible and scalable designs that are simpler and quicker to design and update.

Effective power delivery network

Unlike complex discrete solutions and inflexible “silver box” power systems, power delivery networks using power modules is quick and easy to design and implement. Accommodating new loads — or changes in power needs in a design — is easily accomplished by replacing or adding modules.